Here’s the deal — when you choose a Runchang reducer, we give you an extra 6 months of warranty. Why? Because we believe in what we build. Our confidence comes from consistent quality and a commitment to offering products that outperform in both reliability and price.

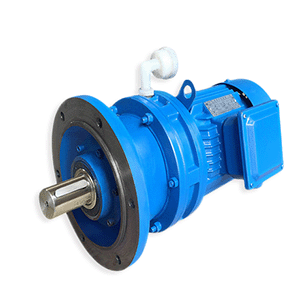

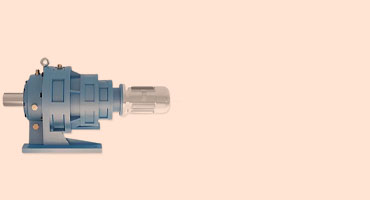

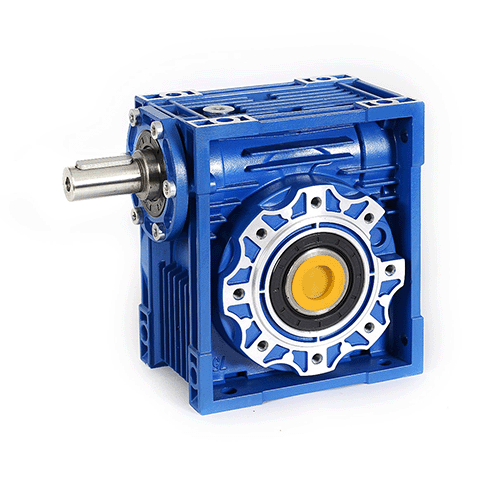

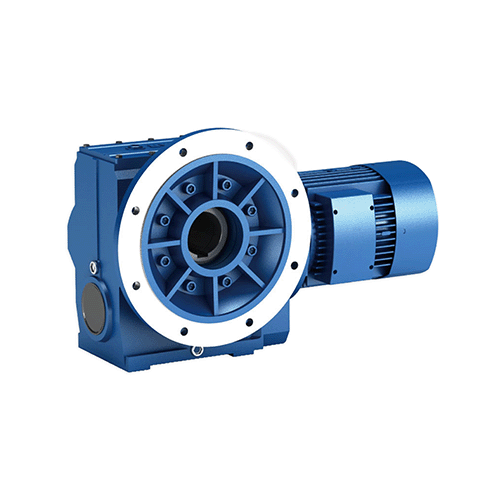

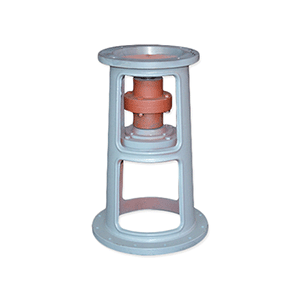

The cycloidal pinwheel reducer is a relatively new type of transmission mechanism, known for its compact structure, high reduction ratio in a single stage, smooth operation, high reliability, and ease of assembly and disassembly. In many cases, it can replace conventional cylindrical gear reducers and worm gear reducers.

A single-stage cycloidal reducer can achieve a reduction ratio of up to 87, while a two-stage system can reach between 121 and 5133, with efficiency exceeding 90%.

Its working principle is similar to that of a planetary gearbox, making the structure quite compact. However, it also has some disadvantages, such as relatively high cost, limited power transmission, and shorter lifespan.

Cycloidal pinwheel reducers are widely used in industries such as petroleum, environmental protection, chemical, cement, conveying, textile, pharmaceutical, food, printing, lifting, mining, metallurgy, construction, and power generation.

- High Reduction Ratio Achieves a reduction ratio of up to 1:87 in a single stage with over 90% efficiency. Even higher ratios are possible with multi-stage transmission.

- Compact Structure & Small Size Based on planetary transmission principles, the input and output shafts are on the same axis, resulting in the smallest possible size.

- Stable Operation & Low Noise With multiple teeth in mesh and a high overlap coefficient, the mechanism is well-balanced, minimizing vibration and noise.

- Reliable & Long Lifespan Key components are made from high-carbon chromium steel, hardened to HRC58–62 for high strength. Rolling friction is used in parts of the transmission for enhanced durability and extended life.

- Smart Design & Easy Maintenance Easy to disassemble and install, with a minimal number of parts and simple lubrication. Compared to other gear reducers of the same power, it is over one-third lighter and smaller. The coaxial input and output shafts further reduce its footprint.

The cycloidal pinwheel reducer is a novel transmission device that applies the principle of planetary gear transmission and uses cycloidal gear meshing. The entire system is composed of three parts: input, reduction, and output. The output shaft is equipped with a double eccentric sleeve that is offset by 180°, and mounted on the sleeve are two needle bearings, forming an H-type mechanism. The center holes of the two cycloidal gears serve as the raceways for the rotating arms of the eccentric sleeves. The cycloidal gears mesh with a ring of needle teeth arranged in a circle on the needle gear, forming an internal gear reduction mechanism with a small difference in the number of teeth.

During operation, the cycloidal gears exhibit both rotation and revolution. For every full rotation of the input shaft, the eccentric sleeve also rotates once, while the cycloidal gears rotate in the opposite direction by one tooth difference — thus achieving the speed reduction effect.

Quality Features of Runccc Gear Reducers

In the gear reducer industry, few dare to boldly promise an "extra six-month warranty"—but Runchang stands out. “Buy Runchang gear reducers and enjoy six months of additional warranty” is not just a slogan; it’s a testament to our confidence in product quality and our commitment to customer satisfaction.

Changzhou Runchang Transmission Machinery Factory has specialized in power transmission equipment for over two decades. As a professional enterprise integrating R&D, design, manufacturing, sales, and service, we are based in Xiaomiao Industrial Park, Minghuang, Wujin District, Changzhou. Our facility is equipped with a full range of high-precision machinery—from injection molding machines to horizontal boring machines, CNC lathes, and machining centers—all dedicated to delivering more stable and durable transmission solutions.

First, we dare to compare materials: we insist on using premium raw materials — never cutting corners.

Second, we dare to compare craftsmanship: meticulous production processes, with every component crafted to perfection.

Third, we dare to compare after-sales service: while others offer a one-year warranty, we offer eighteen months — real quality stands the test of time.

Runchang gear reducers are widely used in automation equipment, packaging machinery, food processing equipment, and more. With service centers established across China, our customers span from north to south. Looking ahead, we aim not only to deliver stable performance, but to ensure long-lasting operation. When it comes to choosing gear reducers, choose the one that dares to offer an extra six-month warranty — choose Runchang. That “dare” comes from years of technical expertise, refined craftsmanship, and trusted service. We don’t tell stories — we prove our strength.

| # |

# |

|---|---|

| # |

# |

| # |

# |

| # |

# |

| # |

# |

| # |

# |

| # |

# |

| # |

# |

| # |

# |

| # |

# |

| # |

# |

| # |

# |

| # |

# |

| # |

# |

Manager Wang

Fuhe Trading Co.

Runccc's cycloidal pinwheel reducer is compact and durable — very impressive. Manager Wang frequently makes inquiries. Thank you for the collaboration.

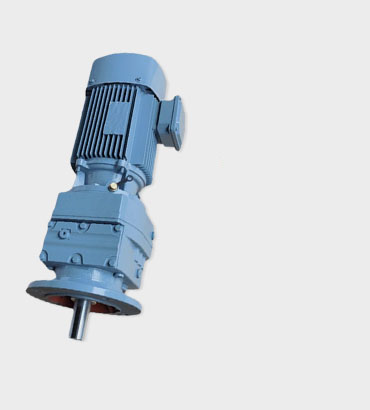

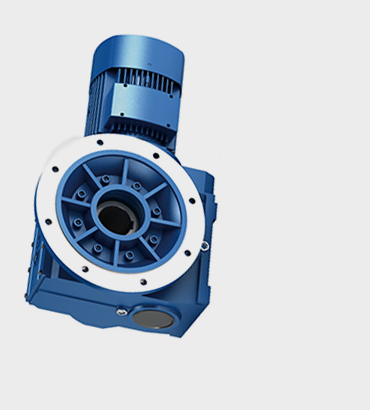

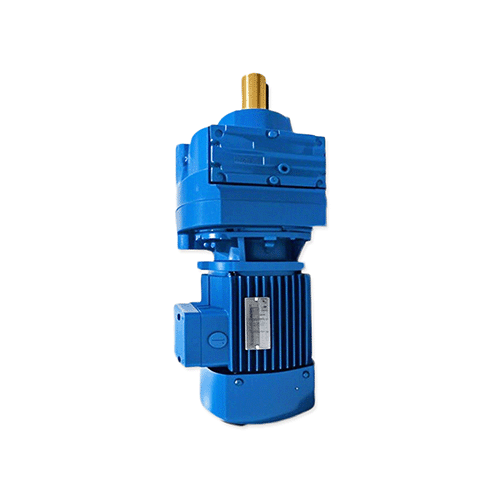

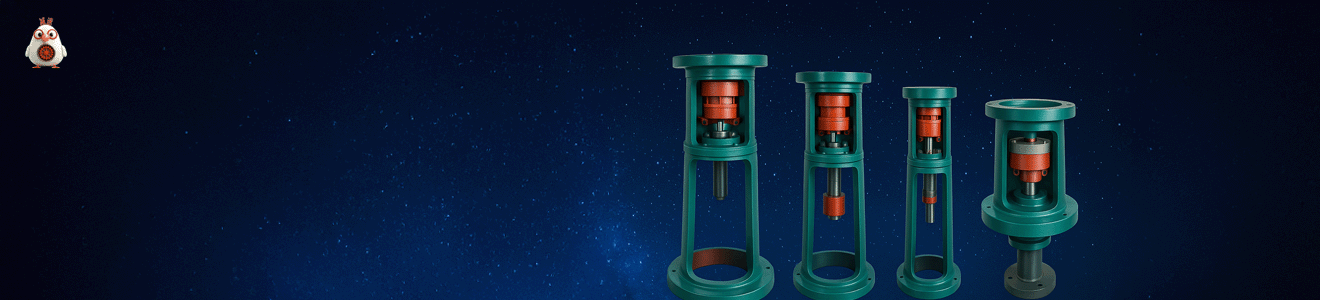

Vertical Single-Stage Cycloidal Pinwheel Reducer

Mr. Liu

Shunde Lifting Machinery

Daring to offer a half-year warranty shows the quality is truly excellent!

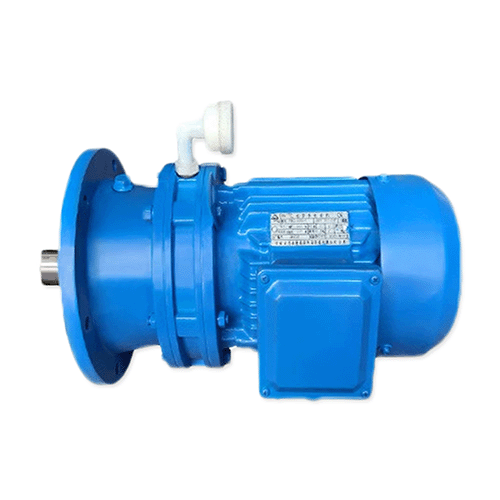

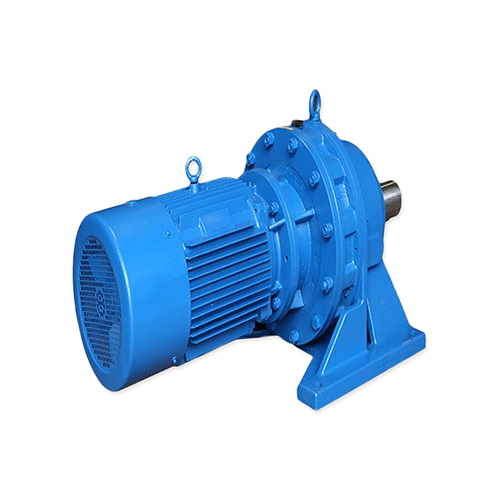

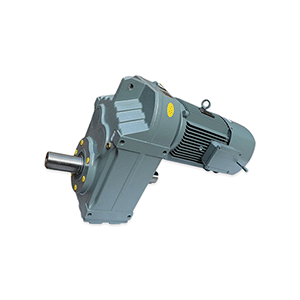

Vertical Double-Stage Cycloidal Pinwheel Reducer

Zhang Decai

Qidong Wangfu Food Co.

We've worked together for many years. Runchang's cycloidal reducers are truly excellent.

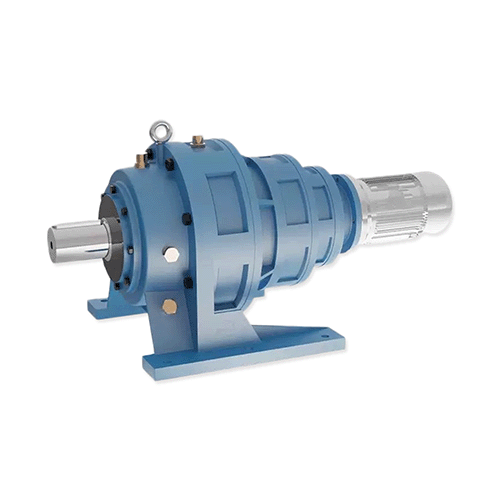

Vertical Double-Stage Cycloidal Pinwheel Reducer